Unique color effects can be seen in melange yarn due to the combination of two or more different colors. These color effects change with the wavy pattern in the yarn.

Types of melange yarns:

- 100% cotton melange

- Cotton-polyester melange (with different percentages)

- Viscose-polyester melange (with different percentages)

- 100% polyester melange

This type of yarn is classified into two main types (in terms of gender):

Mixture: in which, in addition to using different colors, two different genders are combined with each other. Such as cotton polyester melange yarn and viscose polyester melange yarn, which are mixed together in different percentages with different colors.

Non-mixed: yarn in which different fibers are not combined, but different colored fibers of the same species are used to produce yarn, such as 100% cotton melange yarn. or 100% polyester melange yarn.

Production methods

Spun yarn: In this method, melange is produced by using the combination of colored fibers and staple yarn spinning process is used to produce it. This method is used for non-mixed melange yarns (such as 100% cotton, 100% viscose or 100% spun polyester) or mixed melange yarns.

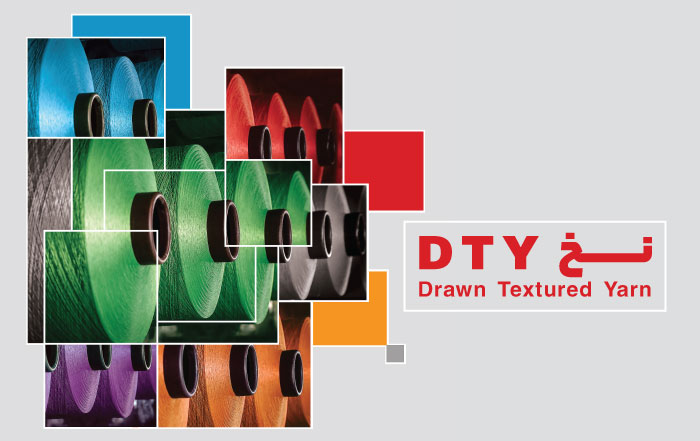

Combined yarn: In this method, separate filament yarns are produced as dope dyed in the spinning process, then two colored filament yarns are combined with each other with the aim of creating the desired color effect.

Important characteristics of melange

Environmentally friendly: because the melange yarn is produced in a colored form, which in some of its color combinations is a raw and undyed component, its production, compared to ordinary yarn, due to the elimination of the dyeing stage of yarn or fabric in water and energy consumption It saves and reduces industrial wastewater and reduces the emission of toxic substances, and for this reason, they can be considered environmentally friendly.

Unique appearance: Melange yarns are very attractive and unique because of the appearance they create in the fabric.

Common problems in melange production

In the production of melange yarns by spinning spun yarns, it is very important to pay attention to the mixing percentage of colored fibers to create a suitable color effect. In addition, during the production process of spun melange yarn, the colored fibers must be well mixed together. If the mixing of colored fibers is not done correctly, it may cause color change in the melange yarn. These problems are less observed in melange yarns that are produced from the combination of filament polyester yarns.

Applications

According to the color effects of melange, it has different uses. For example, it is used in all kinds of sports clothes and warm clothes, all kinds of dress fabrics, all kinds of car seat covers and all kinds of worsted fabrics.

Leave A Comment